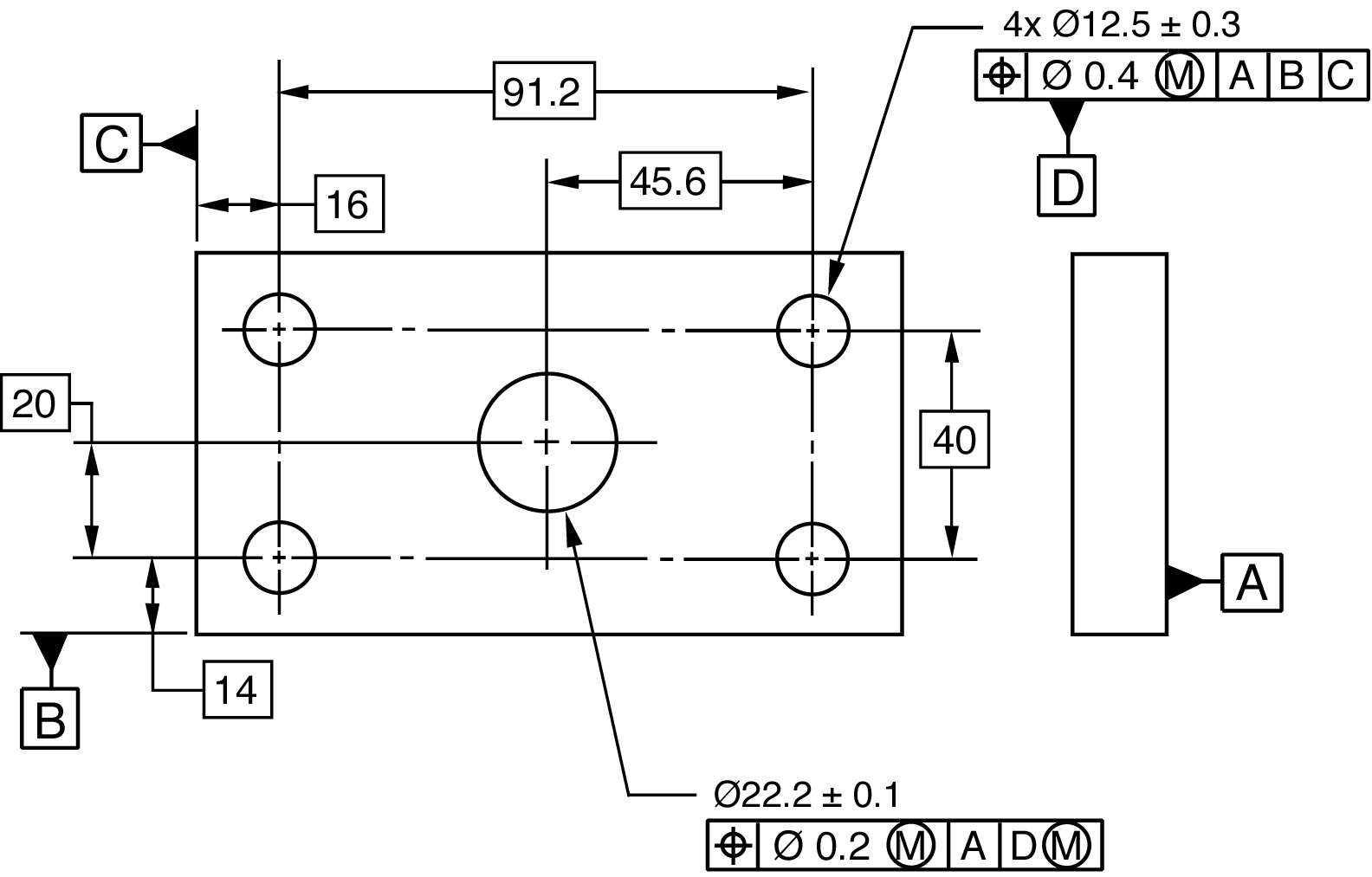

Gd&T Sample Drawing - Gd&t is a way of specifying engineering design and drawing requirements with particular attention to actual function and relationship of.

Gd&T Sample Drawing - Web fundamentals of engineering drawings and gd&t. Web geometric dimensioning and tolerancing is a set of rules and gd&t symbols used on a drawing to communicate the intent of a design, focusing on the function of the part. There are numerous other optional symbols used, which we show at the end of this article. Using gd&t results in a more accurate design, larger tolerances for less important design features, and cost savings for manufacturing. Here is the summary of the key gd & t symbols used in engineering drawings.

Here is the summary of the key gd & t symbols used in engineering drawings. Geometric dimensioning and tolerancing, by d. Gd&t is used to define the nominal (theoretically. And axis and surface and surface t 0.05 “the form of an individual regular feature of size is controlled by its limits of size”. Define part features that would serve as origin with specific directions for measurement this step relates to datums. The tolerance zone is limited by two coaxial cylinders a distance t apart.

GD&T Basics What You Need to Know

Geometric dimensioning and tolerancing, by d. As with all new systems, there is a learning curve with gd&t. Gd&t is used to define the nominal (theoretically. International standard to specify form, fit and function of parts ansi y 14.5, iso 1101 significant improvement over traditional tolerancing focuses on 3d part geometry features in addition to.

Examples on how to interpret GD&T Form, orientation, location and run

Gd&t is used to define the nominal (theoretically. The following slides contain some errors. Web gd&t drawings and symbols geometric tolerances are specified using symbols on a drawing. And axis and surface and surface t 0.05 T 0.03 cylindricity (form tolerance): Currently, we have 16 symbols for geometric tolerances, which are categorized according to the.

GD&T for beginners step by step approach to do gd&t for mechanical

Review the slides use your reference material to find the errors example 1: Web fundamentals of engineering drawings and gd&t. And axis and surface and surface t 0.05 The following slides contain some errors. Using gd&t results in a more accurate design, larger tolerances for less important design features, and cost savings for manufacturing. Web.

Examples on how to interpret GD&T Form, orientation, location and run

Gd&t is used to define the nominal (theoretically. Form control can be additionally refined via ¶ ̧31o. Part features are critical to function or interchangeability And axis and surface and surface t 0.05 These are grouped into symbols relating to form, profile, orientation, runout and location. “the form of an individual regular feature of size.

GD&T Tips Directly Toleranced Dimensions

Web gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and engineering tolerances that helps engineers and manufacturers optimally control variations in manufacturing processes. You’ll receive your score immediately after completing the quiz. “the form of an individual regular feature of size is controlled by its limits of.

What are geometric dimensioning and tolerancing gd t symbols Artofit

Web geometric dimensioning and tolerancing is a set of rules and gd&t symbols used on a drawing to communicate the intent of a design, focusing on the function of the part. Web simple steps towards a correct & complete g d & t drawing step 1: As with all new systems, there is a learning.

GD&T Tips Profile As a General Tolerance

Review the slides use your reference material to find the errors example 1: “the form of an individual regular feature of size is controlled by its limits of size”. Gd&t is used to define the nominal (theoretically. This applies to positive and negative features. In some cases, different terms may refer to the same concept.

Are You Using GD&T Correctly? Geometric Learning Systems

Before the development of gd&t, traditional engineering drawings often contained many handwritten notes to capture the designers. True position, or just position as the asme y14.5 standard calls it, is defined as the total permissible variation that a feature can have from its “true” position. You’ll receive your score immediately after completing the quiz. Currently,.

GD&T Drawings KOHLEX

The “ true position” is the exact coordinate, or location defined by basic dimensions or other means that represents the nominal value. Datums need to be selected based on the following criteria: “the form of an individual regular feature of size is controlled by its limits of size”. This applies to positive and negative features..

GD&T Blog Geometric Learning Systems

True position theory (size value in rectangular frame) classification and symbols of geometric tolerance characteristics The “ true position” is the exact coordinate, or location defined by basic dimensions or other means that represents the nominal value. As with all new systems, there is a learning curve with gd&t. In some cases, different terms may.

Gd&T Sample Drawing Review the slides use your reference material to find the errors example 1: Gd&t is a way of specifying engineering design and drawing requirements with particular attention to actual function and relationship of. Datums need to be selected based on the following criteria: Web gd&t allows for comprehensive and consistent tolerances with the use of relatively simple tools. Parts manufactured in a shop must meet specific design requirements shown on engineering drawings.

As With All New Systems, There Is A Learning Curve With Gd&T.

True position theory (size value in rectangular frame) classification and symbols of geometric tolerance characteristics Web the asme y14.5 is an authoritative guideline and is a design language of geometric dimensioning and tolerancing (gd&t). Datums need to be selected based on the following criteria: Part features are critical to function or interchangeability

Define Part Features That Would Serve As Origin With Specific Directions For Measurement This Step Relates To Datums.

The following slides contain some errors. How to measure straightness flatness the flatness requirement specifies the evenness of a surface, or how accurately flat a target plane should be. Geometric dimensioning and tolerancing, by d. Gd&t is a way of specifying engineering design and drawing requirements with particular attention to actual function and relationship of.

These Are Grouped Into Symbols Relating To Form, Profile, Orientation, Runout And Location.

Before the development of gd&t, traditional engineering drawings often contained many handwritten notes to capture the designers. International standard to specify form, fit and function of parts ansi y 14.5, iso 1101 significant improvement over traditional tolerancing focuses on 3d part geometry features in addition to 2d drawings a typical part drawing when to use gd & t ? Gd&t is used to define the nominal (theoretically. In some cases, different terms may refer to the same concept (e.g.

“The Form Of An Individual Regular Feature Of Size Is Controlled By Its Limits Of Size”.

History of gd&t how did. Web gd&t symbols with examples. And axis and surface and surface t 0.05 Web what is gd & t ?